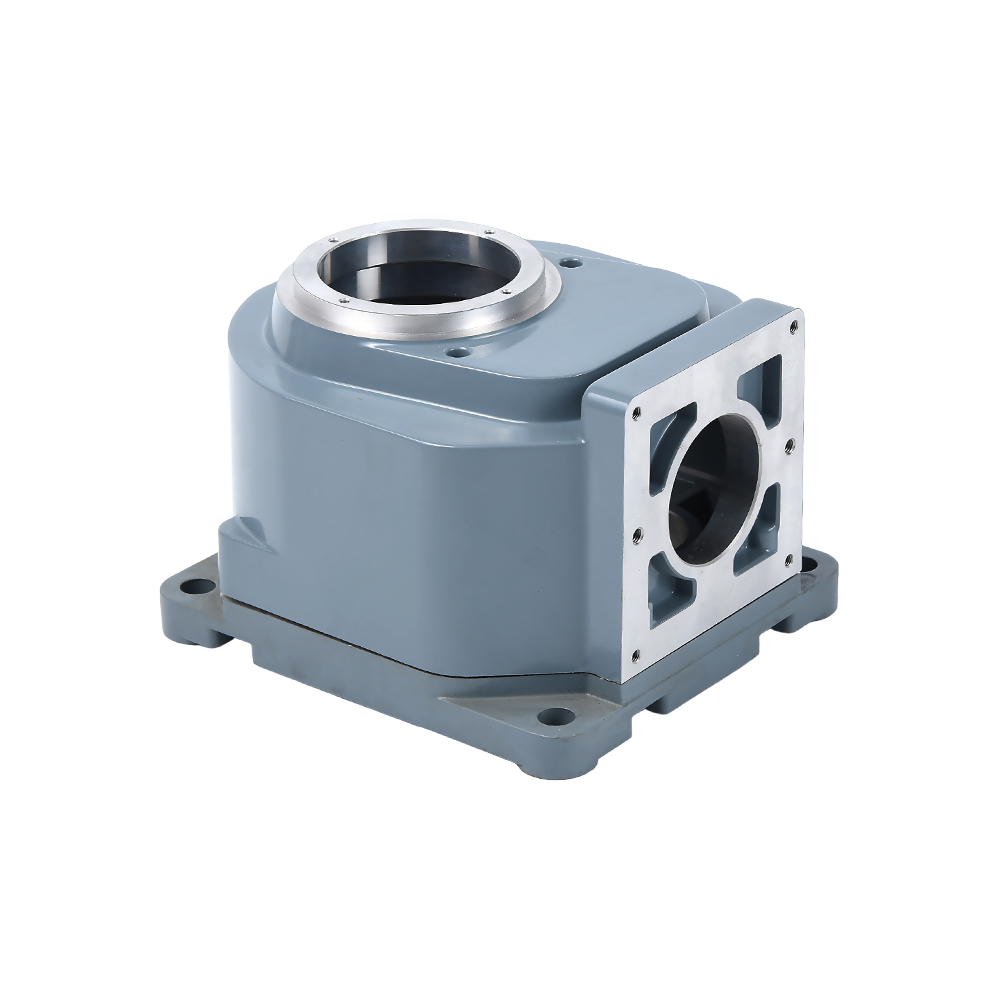

The surface smoothness of parts produced by aluminum die-casting is a complex issue influenced by multiple factors. Firstly, the surface quality of die cast aluminum parts is directly affected by the surface quality of the mold. If the surface smoothness of the mold is high and there are no defects such as unevenness, scratches, and bubbles, then the surface of the produced aluminum parts will often be smoother.

Secondly, the quality of the material is also an important factor determining the surface smoothness of aluminum parts. High quality aluminum materials are easier to flow during the die-casting process and are less prone to defects such as porosity, which helps to achieve a smooth surface.

In addition, the control of production processes is also crucial. Strict control of process parameters such as casting temperature, pressure, speed, and flow rate is required during the die-casting process to ensure the quality of aluminum parts. The reasonable setting and precise control of these parameters can significantly improve the smoothness of the surface of aluminum parts.

However, it is worth noting that even with the highest quality molds, materials, and processes, the surface smoothness of aluminum die castings may be affected by some factors that are difficult to completely eliminate. For example, the stripes that may form during the flow of molten metal and the traces left on the surface of the mold cavity may all affect the surface smoothness of aluminum parts to a certain extent.

In summary, the surface smoothness of parts produced by aluminum die-casting is a relative concept, which is influenced by various factors such as molds, materials, and processes. In actual production, measures such as optimizing mold design, selecting high-quality materials, and strictly controlling production processes can significantly improve the surface smoothness of aluminum die-casting parts to meet the surface quality requirements of different fields.

At the same time, in order to further improve the surface quality of aluminum die castings, subsequent surface treatment processes such as polishing, electroplating, painting, etc. can also be adopted. These processes can further improve the appearance quality of aluminum parts, making their surfaces smoother and more aesthetically pleasing. However, it should be noted that the selection of surface treatment processes should be determined based on specific application scenarios and requirements to ensure optimal results.

English

English русский

русский Español

Español