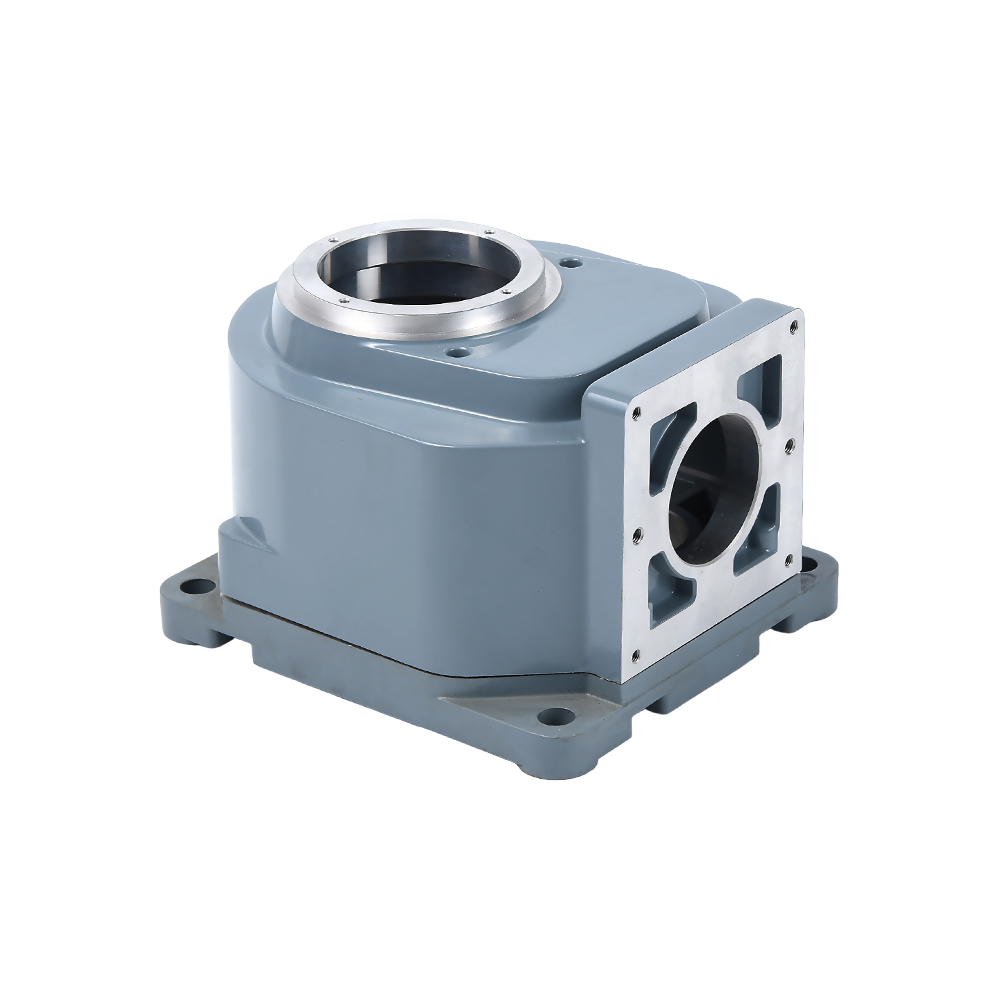

The main materials of Automobile Cylinder Body Parts include cast iron, aluminum alloys, and in some high-performance applications, special materials such as titanium or carbon fiber composites. Each material has its own unique advantages and challenges.

Cast Iron: Traditional cast iron cylinder blocks are known for their strength and durability, allowing them to withstand the extreme pressures and temperatures found inside the engine. However, they are also heavy, which can negatively impact fuel economy and increase emissions.

Aluminum Alloys: Aluminum alloys are becoming more and more popular due to their perfect combination of strength, lightweight properties and good thermal conductivity. An aluminum cylinder block can significantly reduce the overall weight of the engine, thereby improving fuel economy and reducing emissions. Additionally, its high thermal conductivity helps maintain optimal engine temperatures, improving performance and durability.

Specialty materials: Titanium and carbon fiber composites can save more weight and increase performance potential, but cost significantly more. These materials are often used in high-end sports car and racing applications, where every gram counts.

Performance and durability

The performance and durability of Automobile Cylinder Body Parts are closely related to the materials used. Stronger materials can withstand higher pressures and temperatures, resulting in more efficient and powerful engines. However, strength alone is not enough; the material must also be able to withstand the constant vibration, thermal cycling and wear that occurs during engine operation.

Material selection for Automobile Cylinder Body Parts has a direct impact on fuel economy and emissions. Lightweight materials such as aluminum alloys reduce the overall weight of the engine and vehicle, thereby lowering fuel consumption and reducing CO2 emissions. In addition, the aluminum alloy's improved thermal conductivity helps maintain optimal engine temperatures, improve combustion efficiency and further reduce emissions.

In addition to material selection, the design and manufacturing processes of Automobile Cylinder Body Parts also play a role in optimizing fuel economy and emissions. Advanced casting and forging techniques and precision machining help reduce material waste and improve consistency between parts, thereby increasing engine efficiency.

English

English русский

русский Español

Español