Aluminum die-casting technology can be fully used for producing automotive parts. Aluminum die-casting is a method of forming castings with predetermined shapes, sizes, and properties by injecting molten aluminum into the die-casting mold of a die-casting machine, cooling and solidifying it. This method has the advantages of high production efficiency, high dimensional accuracy of castings, good surface smoothness, good mechanical properties, and the ability to cast complex and thin-walled parts. Therefore, it is very suitable for producing automotive parts.

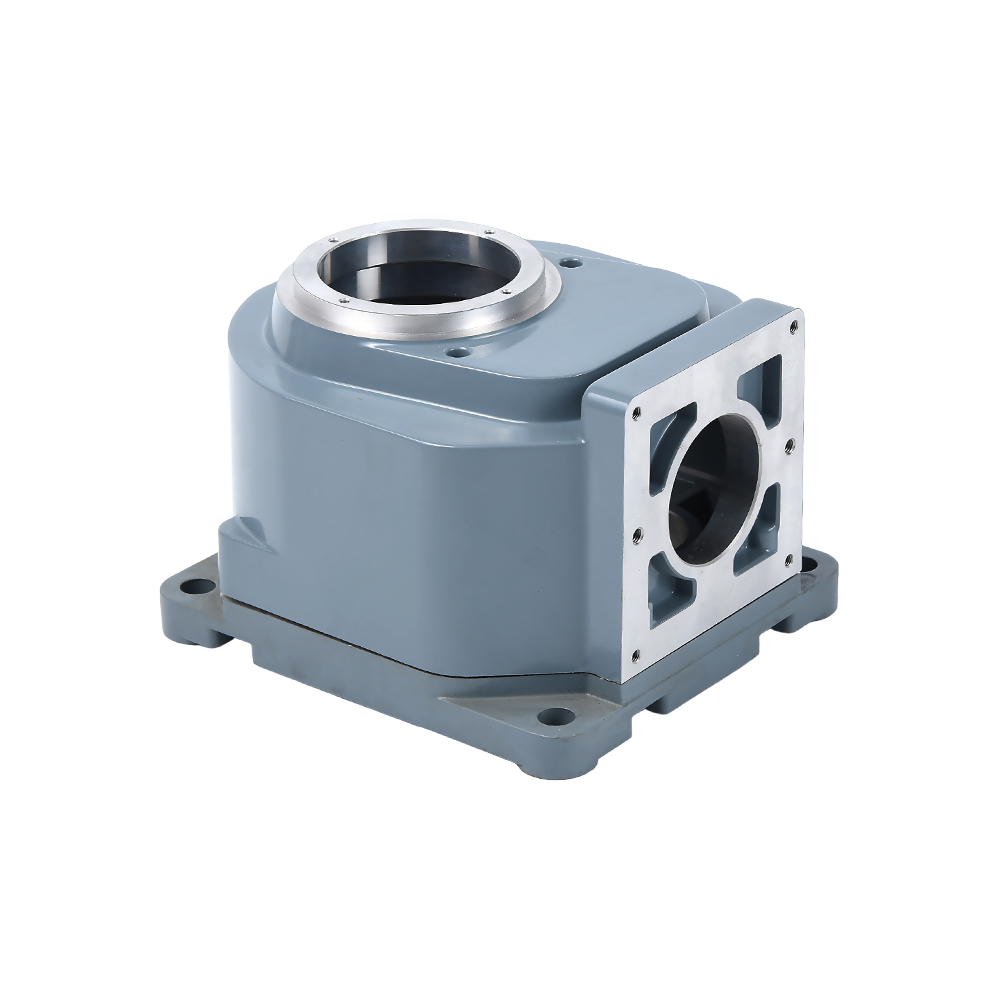

In the automotive industry, aluminum die castings are widely used in various systems such as engines, transmissions, chassis, and vehicle bodies, such as engine cylinder blocks, cylinder heads, oil pans, transmission housings, suspension system components, wheel hubs, etc. These aluminum die castings not only reduce the overall weight of the car, improve fuel economy and vehicle performance, but also have good corrosion resistance and fatigue resistance, ensuring the safety and reliability of the car.

In addition, with the accelerated development of the trend towards lightweighting in automobiles, the application of aluminum die castings in automotive manufacturing is becoming increasingly widespread. In order to meet the complexity and performance requirements of different automotive components, aluminum die-casting technology is constantly developing and innovating, such as adopting advanced die-casting processes and equipment, optimizing die-casting mold design, improving aluminum liquid quality, and other measures to further enhance the quality and performance of aluminum die-casting parts.

English

English русский

русский Español

Español