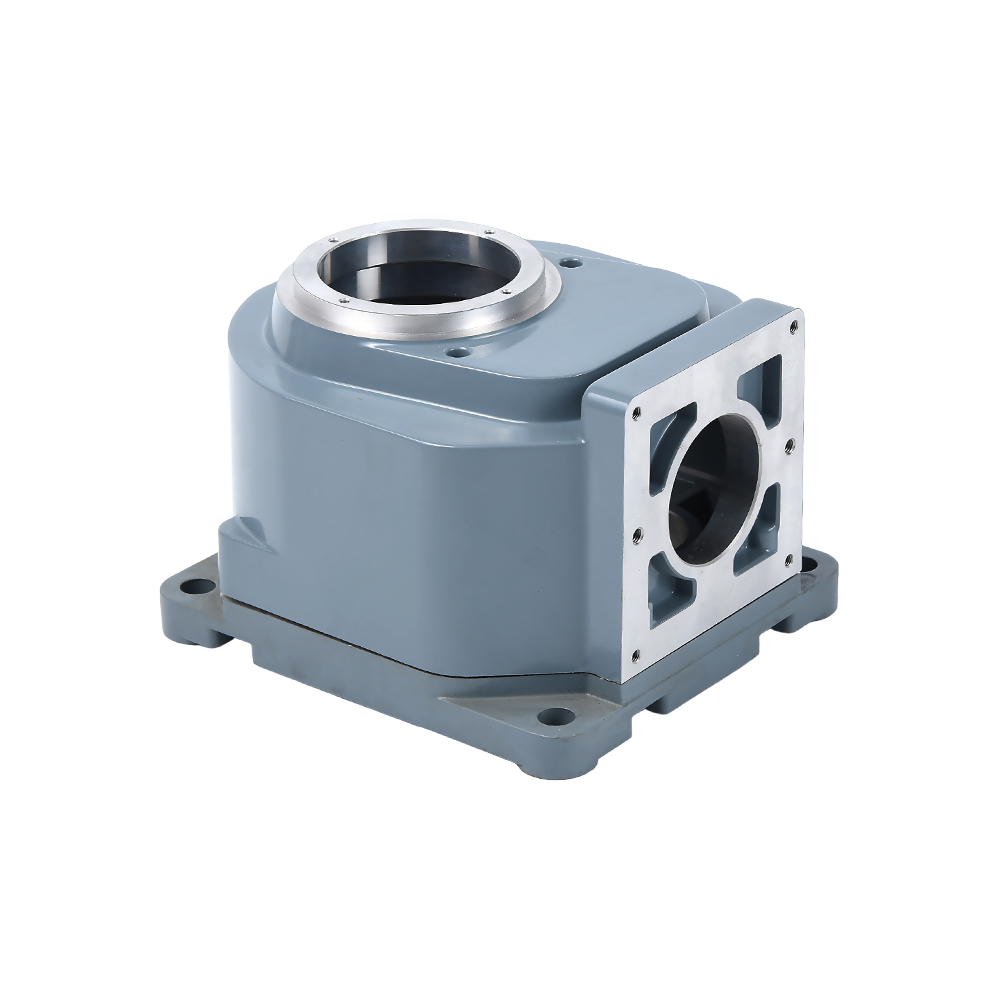

Aluminum die-casting can indeed be used to produce internal combustion engine components. Aluminum and aluminum alloys have been widely used in the production of internal combustion engine components due to their excellent thermal conductivity, low specific gravity, and high processability. Aluminum die-casting parts are parts made from metal aluminum or aluminum alloy as the main raw material through pressure casting technology, which is very suitable for producing complex shaped and high-precision internal combustion engine components.

In internal combustion engines, aluminum die castings have a wide range of applications, including but not limited to key components such as engine cylinder blocks, cylinder heads, crankcases, oil pans, intake and exhaust manifolds. These components are produced using aluminum die-casting technology, which not only reduces the overall weight of the internal combustion engine and improves fuel economy, but also reduces emissions and enhances the overall performance of the internal combustion engine.

Specifically, the advantages of aluminum die castings in the production of internal combustion engine components are mainly reflected in the following aspects:

Lightweight: The density of aluminum is much lower than traditional materials such as steel, so the use of aluminum die castings can significantly reduce the weight of internal combustion engines, helping to improve the fuel economy and handling performance of vehicles.

Good heat dissipation: Aluminum and aluminum alloys have good thermal conductivity, which enables aluminum die castings to dissipate heat more effectively in high-temperature environments of internal combustion engines, ensuring stable operation of the engine.

Strong machinability: Aluminum and aluminum alloys have excellent machinability and are suitable for various processes such as casting, forging, stamping, etc. They can produce complex shaped and high-precision internal combustion engine components.

Cost effectiveness: Although the price of aluminum is relatively high, considering its long-term benefits such as improved fuel economy and reduced emissions brought about by lightweighting, the cost-effectiveness of aluminum die-casting in the production of internal combustion engine components is significant.

English

English русский

русский Español

Español