Aluminum die-casting technology can indeed be used to produce electronic equipment components and has broad application prospects in this field. With the rapid development of electronic technology, the requirements for appearance design, performance optimization, and reliability are constantly increasing. Aluminum die-casting technology has become an important choice in the manufacturing of electronic equipment components due to its unique advantages.

Firstly, aluminum die-casting technology can achieve lightweighting of components. Electronic devices typically require portability, and aluminum die-casting technology can significantly reduce their weight while maintaining component strength, providing better assurance for the portability and user experience of electronic devices.

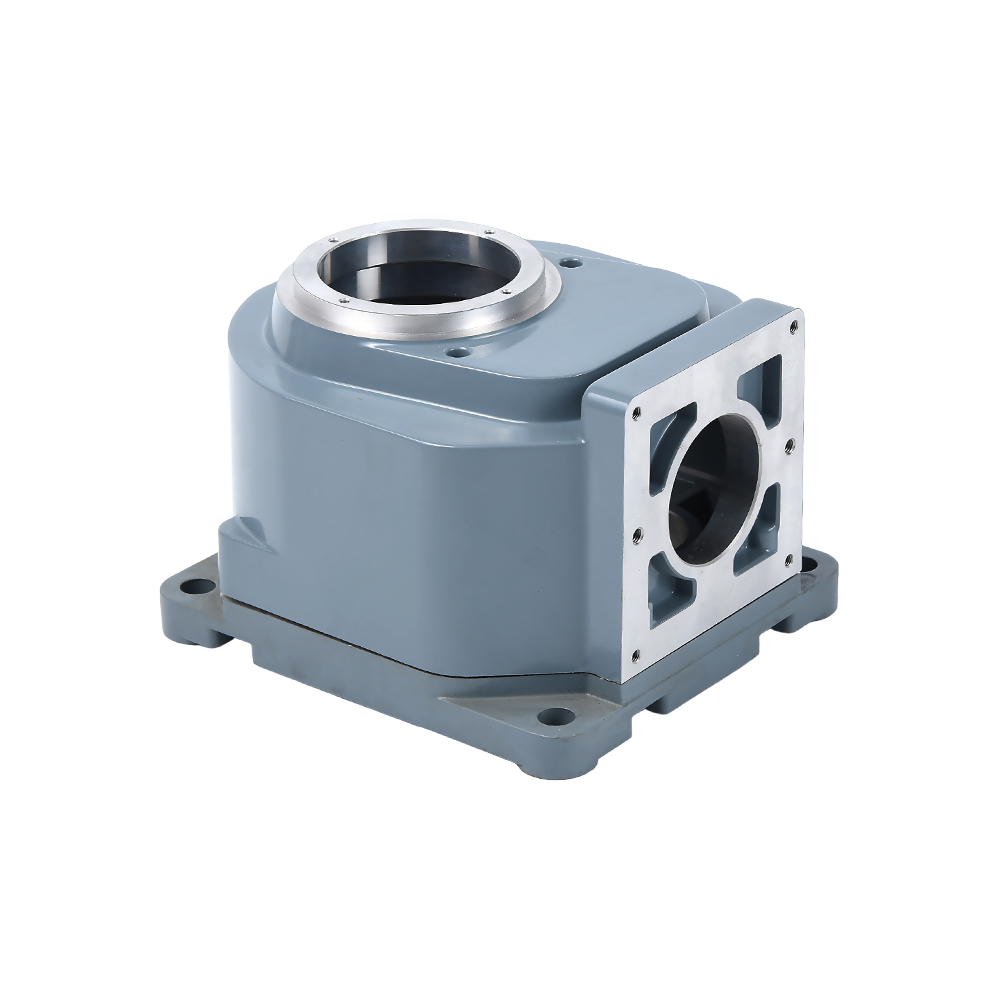

Secondly, aluminum die-casting technology can produce precise and complex structures. Electronic device components often need to accommodate various components and interfaces, with very high requirements for structural design. The aluminum die-casting process can manufacture precise and complex structures that meet these requirements through high-pressure injection molding, ensuring the functionality and aesthetic appearance of the components.

In addition, aluminum has excellent thermal conductivity, which is crucial for the heat dissipation of electronic devices. Components manufactured using aluminum die-casting technology can effectively dissipate heat, improve equipment heat dissipation efficiency, and ensure long-term stable operation of the equipment.

At the same time, aluminum die-casting technology also has high flexibility and plasticity, which can easily shape various appearance effects to meet the aesthetic and functional needs of different users. This also gives aluminum die-casting technology great advantages in personalized design of electronic equipment components.

Finally, from the perspective of environmental protection and sustainable development, aluminum is a recyclable material, and the aluminum die-casting process has relatively low resource consumption, which is in line with the current trend of green manufacturing. This provides a more environmentally friendly and sustainable option for the manufacturing of electronic device components.

In summary, aluminum die-casting technology can be fully used to produce electronic device components, and has significant advantages in lightweight, precision structure, heat dissipation performance, personalized design, and environmental protection characteristics. With the continuous evolution of electronic device technology, the application prospects of aluminum die-casting process in the field of electronic device component manufacturing will be even broader.

English

English русский

русский Español

Español