1. Material selection

Selection of aluminum alloy: Aluminum alloy is widely used in medical implants due to its light weight, high strength and good corrosion resistance. By selecting the right aluminum alloy material, it can be ensured that the prosthesis has sufficient strength and rigidity while maintaining a light weight for patients to wear and use.

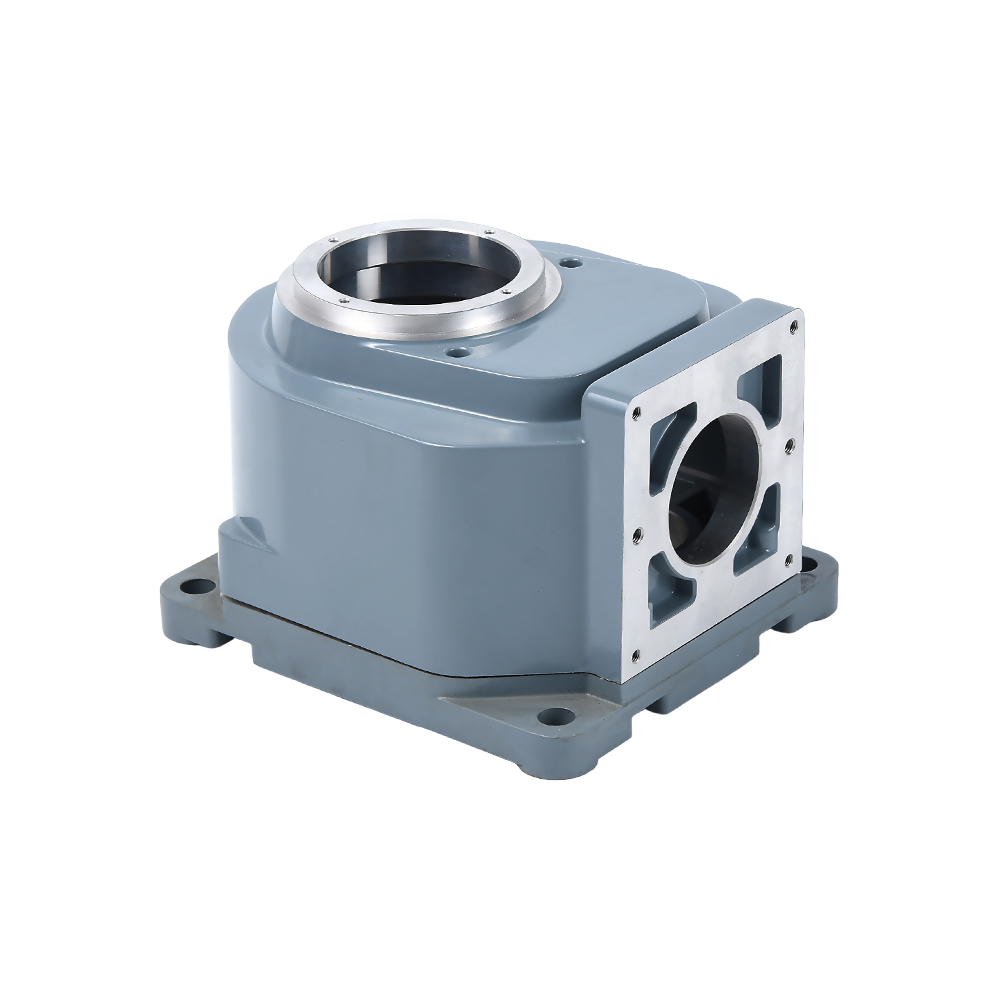

2. Structural design

Design of complex shapes: The Aluminum Cast Implantation Arm is designed with complex shapes to meet the specific needs of patients. These designs include the flexibility of the joints, the strength of the joints, and the stability of the overall structure. Through precise calculations and simulations, it can be ensured that the prosthesis will not deform or damage when it is subjected to the loads required for daily use.

Modular design: The modular design allows the prosthesis to be customized and adjusted according to the needs of the patient. Different modules can be interchanged to adapt to different usage scenarios and patient needs. This design not only improves the adaptability of the prosthesis, but also facilitates maintenance and replacement.

3. Casting process

Precise casting process: Precise casting technology is used in the manufacturing process of the Aluminum Cast Implantation Arm. By controlling parameters such as temperature, pressure and filling speed during the casting process, it is possible to ensure that the aluminum liquid flows evenly in the mold and fills the entire mold, thereby obtaining a prosthetic arm with accurate shape and complete structure.

Heat treatment: In order to improve the strength and hardness of the prosthetic arm, heat treatment is usually required. Through the heating and cooling process, the microstructure of the aluminum alloy can be changed, thereby improving its mechanical properties.

IV. Customized adaptation

Consideration of individual needs of patients: When designing and manufacturing the Aluminum Cast Implantation Arm, the individual needs of patients are fully considered. By collecting information such as the patient's physical data, exercise habits, etc., the prosthetic arm can be tailored for the patient to ensure that it meets the patient's anatomical structure and functional needs.

Adjustable and replaceable parts: In order to adapt to the different needs of patients, the Aluminum Cast Implantation Arm is usually equipped with adjustable and replaceable parts. These parts can be adjusted or replaced according to the needs of the patient to ensure the continued effectiveness and comfort of the prosthetic arm.

V. Biocompatibility considerations

Biocompatibility of aluminum alloys: When selecting aluminum alloy materials, its biocompatibility is considered. By selecting appropriate alloy composition and manufacturing process, good compatibility between aluminum alloy and human tissue can be ensured, reducing the risk of rejection and infection.

English

English русский

русский Español

Español