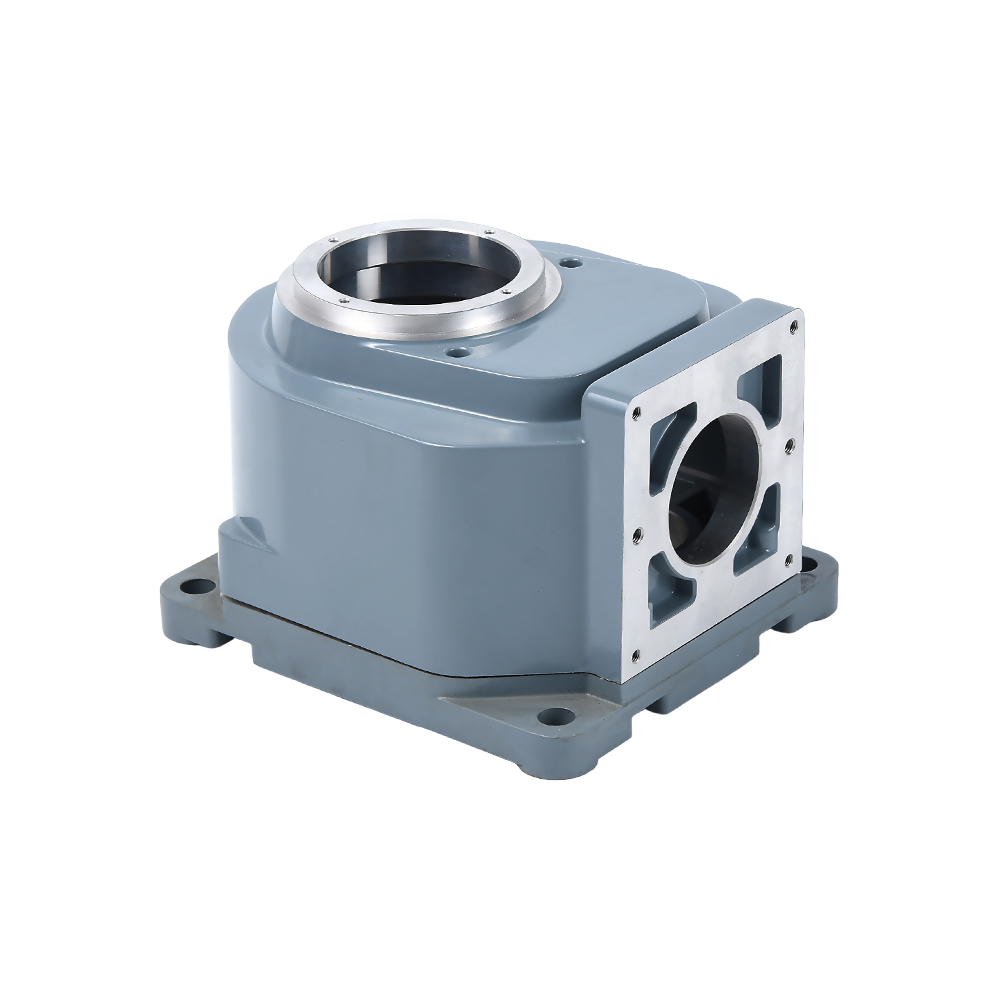

High Strength:

The aluminum die casting process is able to produce Aluminun Die Casting Motor Guard Plate with high strength characteristics by precisely controlling the mold and the injection process of molten metal. This strength ensures that the guard plate can maintain its integrity and functionality when subjected to external impact and pressure.

High Precision:

The design of aluminum die casting molds is very precise and can replicate very complex geometries and details. This means that the Aluminun Die Casting Motor Guard Plate can have complex internal structures and high-precision dimensional tolerances to meet strict assembly and functional requirements.

Good Surface Quality:

The Aluminun Die Casting Motor Guard Plate produced by the aluminum die casting process usually has a smooth, seamless surface, which helps reduce friction and wear while improving aesthetics. In addition, this smooth surface is also easy to clean and maintain.

Lightweight:

Aluminum is a lightweight metal, and the Aluminun Die Casting Motor Guard Plate can significantly reduce weight compared to traditional materials such as steel. This is essential for improving vehicle fuel efficiency, reducing emissions and enhancing vehicle handling.

Excellent corrosion resistance:

Aluminun Die Casting Motor Guard Plate can show good corrosion resistance after proper surface treatment (such as anodizing or coating). This helps to extend the service life of the guard plate while reducing maintenance and replacement costs.

Good thermal conductivity:

Aluminum is a good thermal conductor, which means that Aluminun Die Casting Motor Guard Plate can effectively dissipate heat and protect the motor from overheating damage. This is essential to ensure the long-term stable operation of the motor.

English

English русский

русский Español

Español