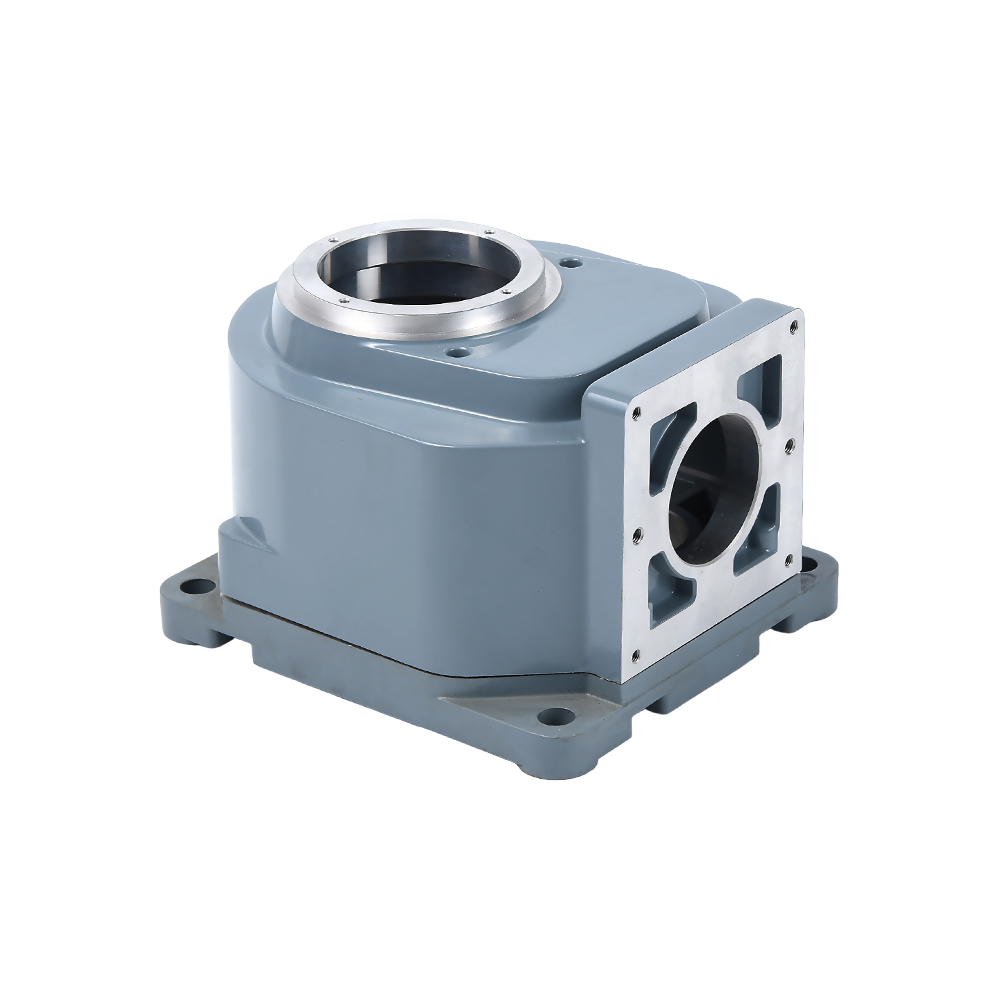

Regulating the flow of hydraulic fluid through aluminun die casting hydraulic valves mainly depends on the precise design of the valve body, the motion control of the valve core, and the adjustment of the fluid channel.

1. Valve core position control: The precise movement of the valve core in the valve body controls the flow. Common valve core types include slide valves, ball valves, and plunger valves. The position of the valve core determines the channel area through which the fluid passes, thereby regulating the flow.

2. Flow control valve: The flow control valve changes the flow channel opening by rotating or adjusting the control device to fine-tune the flow. The proportional valve uses an external electrical signal or hydraulic signal to smoothly adjust the flow and is suitable for high-precision control.

3. Pressure compensation: The pressure compensation valve automatically adjusts the flow according to the change of system pressure, maintains a stable flow output, and avoids pressure fluctuations affecting system performance.

4. Proportional control system: The proportional valve controls the valve core through electronic or hydraulic signals to accurately adjust the flow, which is particularly suitable for dynamic adjustment needs.

5. Multi-way valve and diversion regulation: The multi-way valve can distribute the flow between multiple circuits to provide the required flow for different actuators.

6. Precision flow channel design: Aluminum die-casting process ensures accurate flow channel size, reduces flow resistance and improves flow regulation accuracy.

English

English русский

русский Español

Español