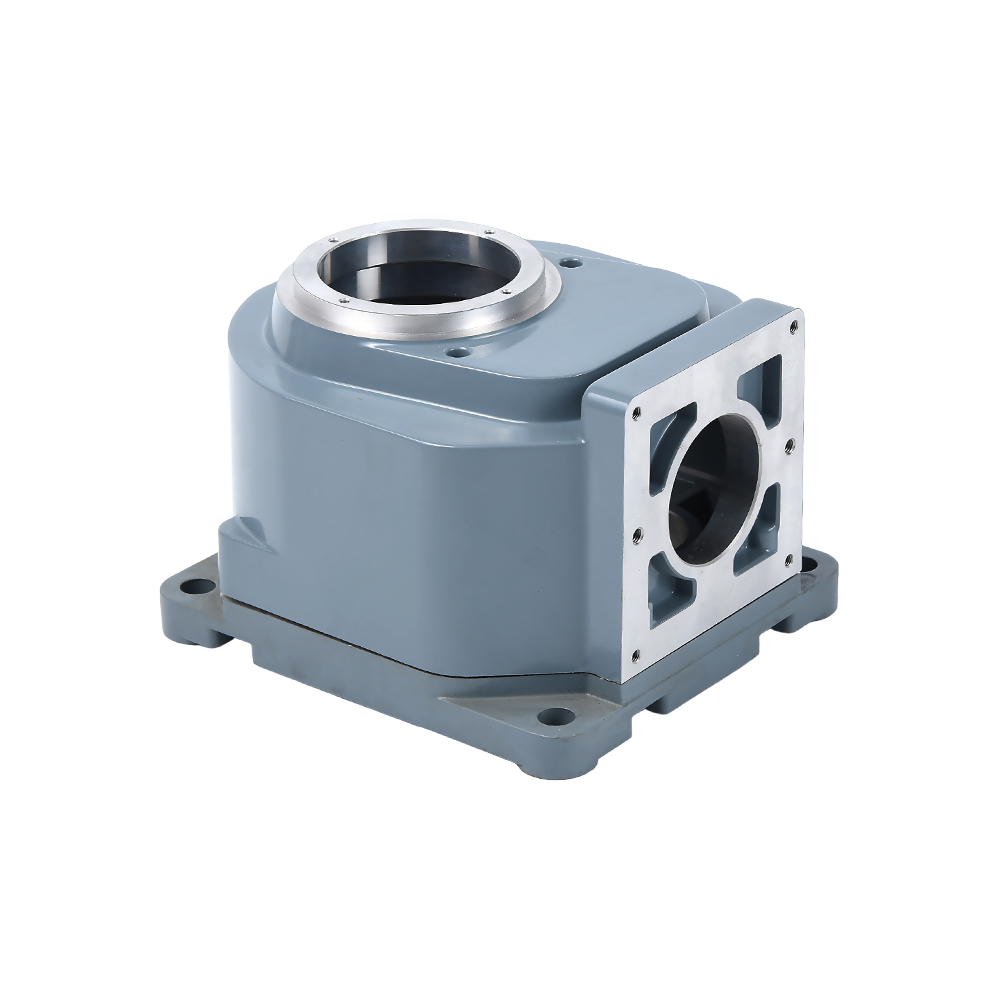

The advantages of aluminun die casting gearbox housings are mainly reflected in the following aspects:

1. Lightweight designa

Reducing the weight of the whole vehicle: Aluminum alloy has a lower density. Compared with traditional steel housings, aluminum die-cast gearbox housings can significantly reduce the overall weight of automobiles or mechanical equipment. This helps to improve fuel efficiency, extend the range of electric vehicles, and improve handling and maneuverability.

Improve fuel efficiency and endurance: Lightweighting directly reduces the load on the power system, thereby improving fuel economy, which is especially important in electric vehicles and hybrid vehicles.

2. High durability and corrosion resistance

Corrosion resistance: Aluminum alloys have natural corrosion resistance and can resist corrosion from moisture, salt water and other chemicals. This makes aluminum die-cast gearbox housings particularly suitable for harsh environments and prolongs the service life of the gearbox.

High temperature resistance and fatigue resistance: Aluminum alloys have strong stability in high temperature environments, adapt to the needs of long-term operation of gearboxes under high loads, and have strong fatigue resistance, avoiding cracks and deformation under repeated loads.

3. Precision Manufacturing and Complex Shapes

High-precision manufacturing: Aluminum die-casting technology can accurately control the casting process and produce gearbox housings with complex shapes and fine structures, meeting the requirements of modern gearbox design for details and structural accuracy.

Support for complex designs: Through die-casting, complex inner cavity structures can be produced, such as channels, reinforcing ribs and other designs, which improve the strength and functionality of the gearbox.

4. Excellent thermal management capabilities

Strong thermal conductivity: Aluminum has good thermal conductivity, which helps to quickly dissipate heat, keep the temperature in the gearbox within the normal working range, avoid overheating and damage to internal gears and components, and improve the overall stability and life of the system.

5. Environmental protection and sustainability

Recyclability: Aluminum is a recyclable material. The use of aluminum alloy gearbox housings meets the requirements of modern environmental protection and sustainable development, reducing resource waste.

Reduced emissions: By reducing the weight of the car, aluminum die-cast gearbox housings help reduce carbon dioxide emissions and support green and environmentally friendly automotive design concepts.

6. Cost-effectiveness and production efficiency

Fast production and high precision: The aluminum die-casting process is suitable for large-scale production and can produce high-precision gearbox housings in a short time, reducing manufacturing cycles and costs.

Reduce post-processing: Aluminum die-cast gearbox housings usually have good dimensional accuracy, which reduces post-processing steps and improves production efficiency.

7. Improve vehicle performance

Improve handling: Lightweight aluminum die-cast gearbox housings can reduce the total weight of the vehicle, making the vehicle more flexible during acceleration, braking and steering, and improving the driving experience.

Enhance power transmission efficiency: Lightweight and precision design help improve the working efficiency of the gearbox and optimize the response speed and transmission stability of the power transmission system.

English

English русский

русский Español

Español