Web Menu

Product Search

Exit Menu

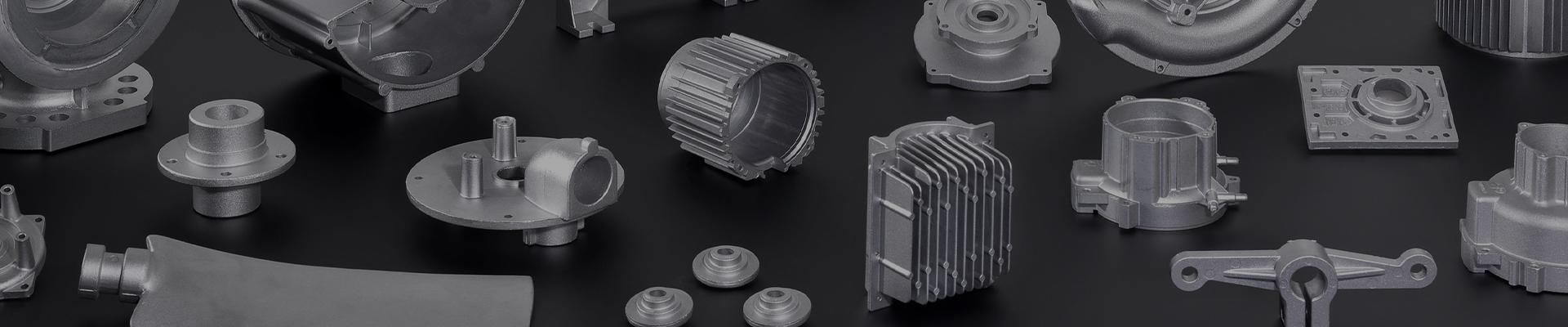

Product Series

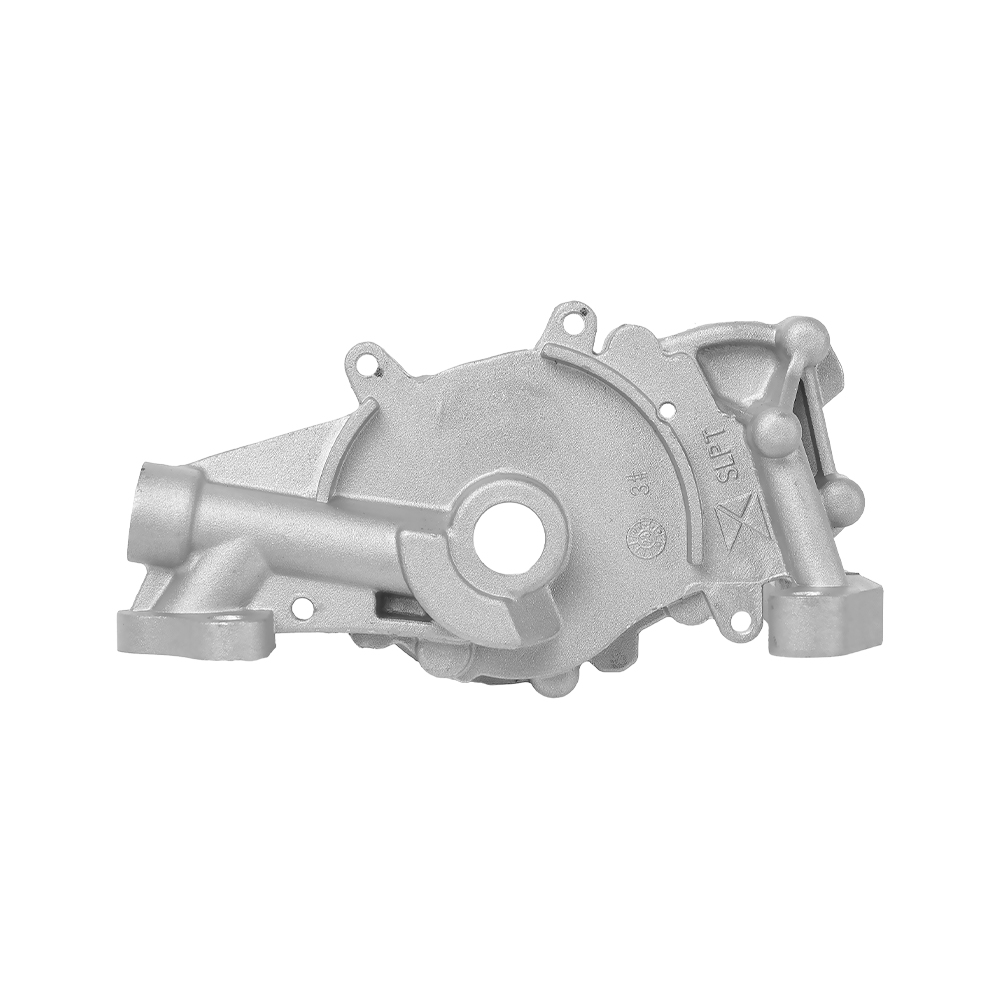

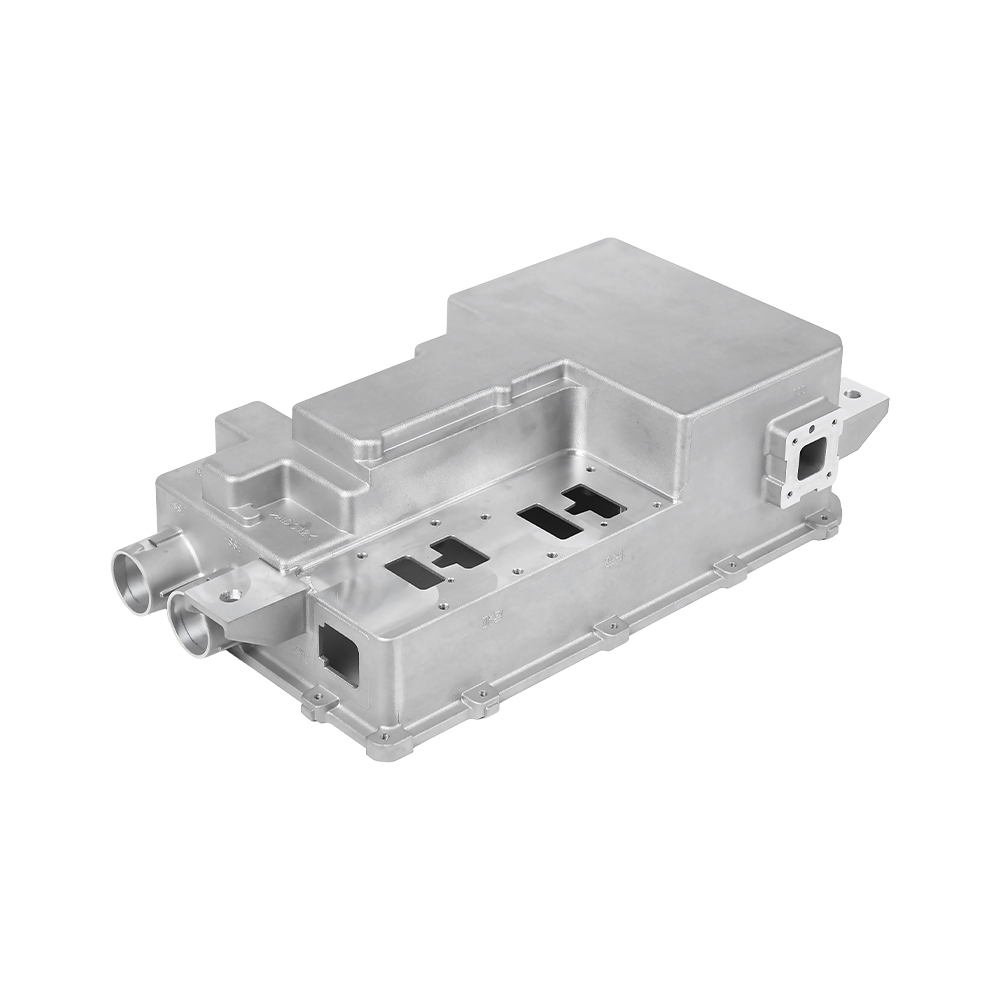

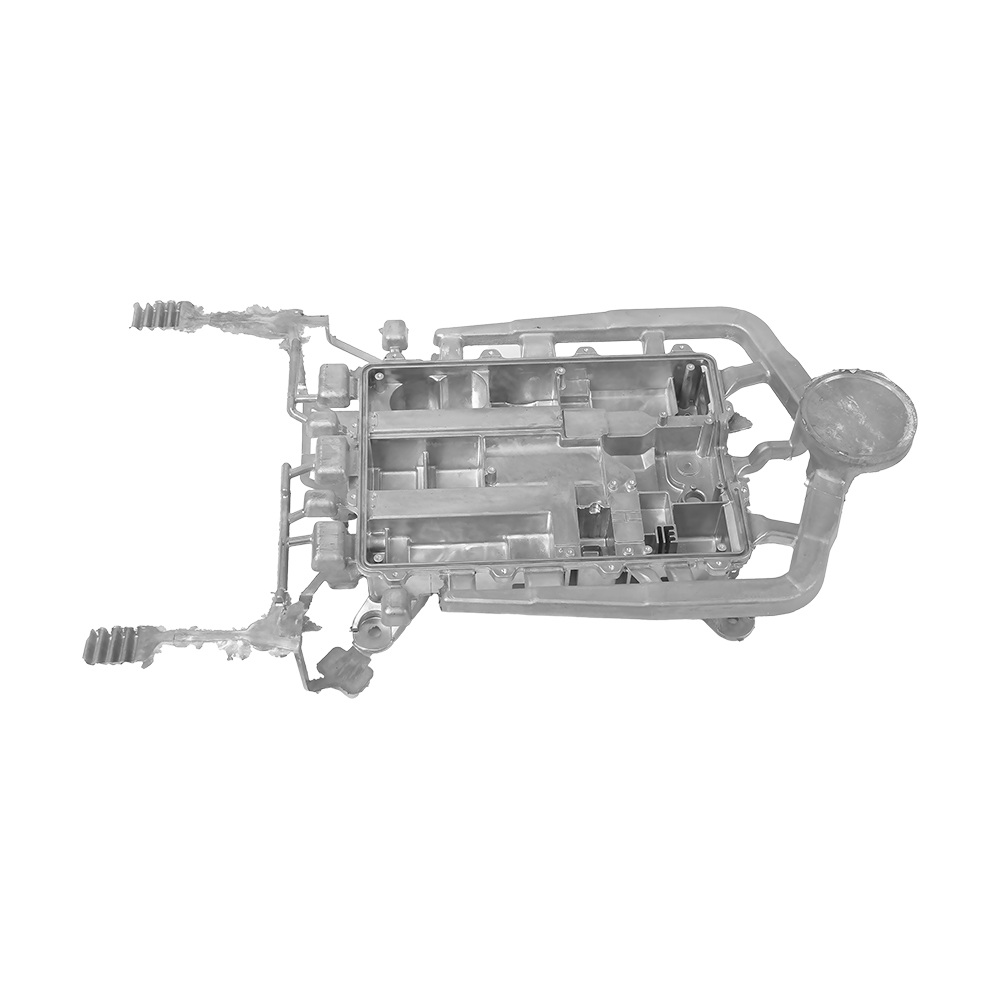

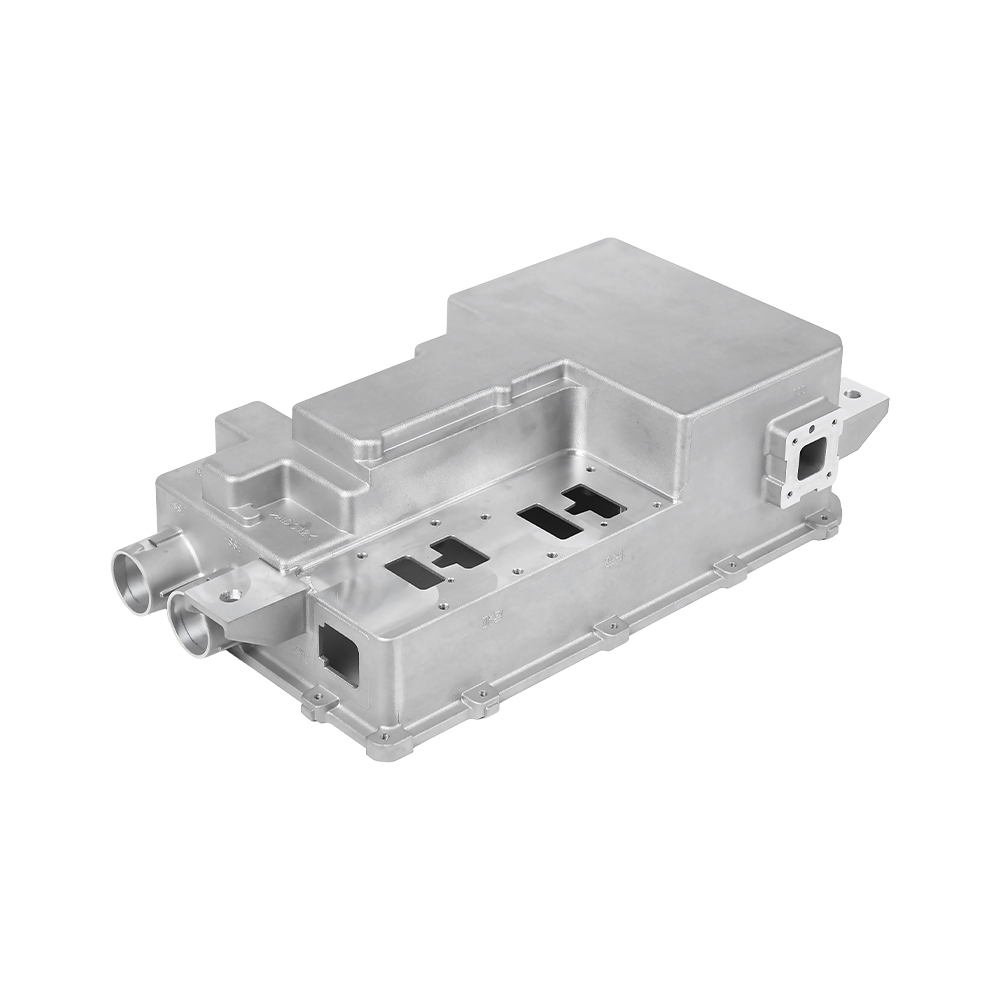

Aluminum Cast Car Engine Parts Oil Pump

- Description

- Contact Us

Related Products

-

Aluminum Casting Accessories Aluminum End Cap

Cat:Aluminum Die Casting

This Aluminum Casting Accessory, the Aluminum End Cap, is crafted from high-quality aluminum alloy m...

See Details -

New Energy Vehicle Heat Dissipation Aluminum Substrate

Cat:Aluminum Die Casting

This new energy vehicle utilizes an aluminum alloy substrate for heat dissipation, employing high-qu...

See Details -

Aluminum Die Cast Motor Housing 375

Cat:Aluminum Die Casting

Aluminum Die Cast Motor Housing 375 is a kind of metal shell used to protect the motor. Its main fun...

See Details -

Opening Machine Accessories

Cat:Aluminum Die Casting

Aluminum pressure casting is the main part of the aluminum pressure die-casting machine, manufacture...

See Details -

Aluminum Die Casting Hydraulic Valve

Cat:Aluminum Die Casting

Aluminum die-casting hydraulic valve represents a pinnacle of engineering precision and efficiency i...

See Details -

Aluminum Die Casting Gasoline Engine Case

Cat:Aluminum Die Casting

Aluminum die casting for gasoline engine cases is a sophisticated manufacturing process that plays a...

See Details -

Car Air Conditioning Aluminum Compressor Cylinder

Cat:Aluminum Die Casting

Our aluminum engine cylinder block is a high-quality automotive component made from high-purity alum...

See Details -

Aluminum Die Casting Gearbox Body

Cat:Aluminum Die Casting

High Precision: Utilizing precision aluminum alloy die-casting technology ensures the product's dime...

See Details -

Aluminum Bearing Bracket

Cat:Aluminum Die Casting

The Aluminum Bearing Bracket is a crucial mechanical component employed to support and secure bearin...

See Details -

Auto Engine Cooling Water Pump

Cat:Aluminum Die Casting

This product is an efficient automotive engine cooling water pump, manufactured using high-quality m...

See Details -

Aluminum Casting Accessories Aluminum End Cap

Cat:Aluminum Die Casting

This Aluminum Casting Accessory, the Aluminum End Cap, is crafted from high-quality aluminum alloy m...

See Details -

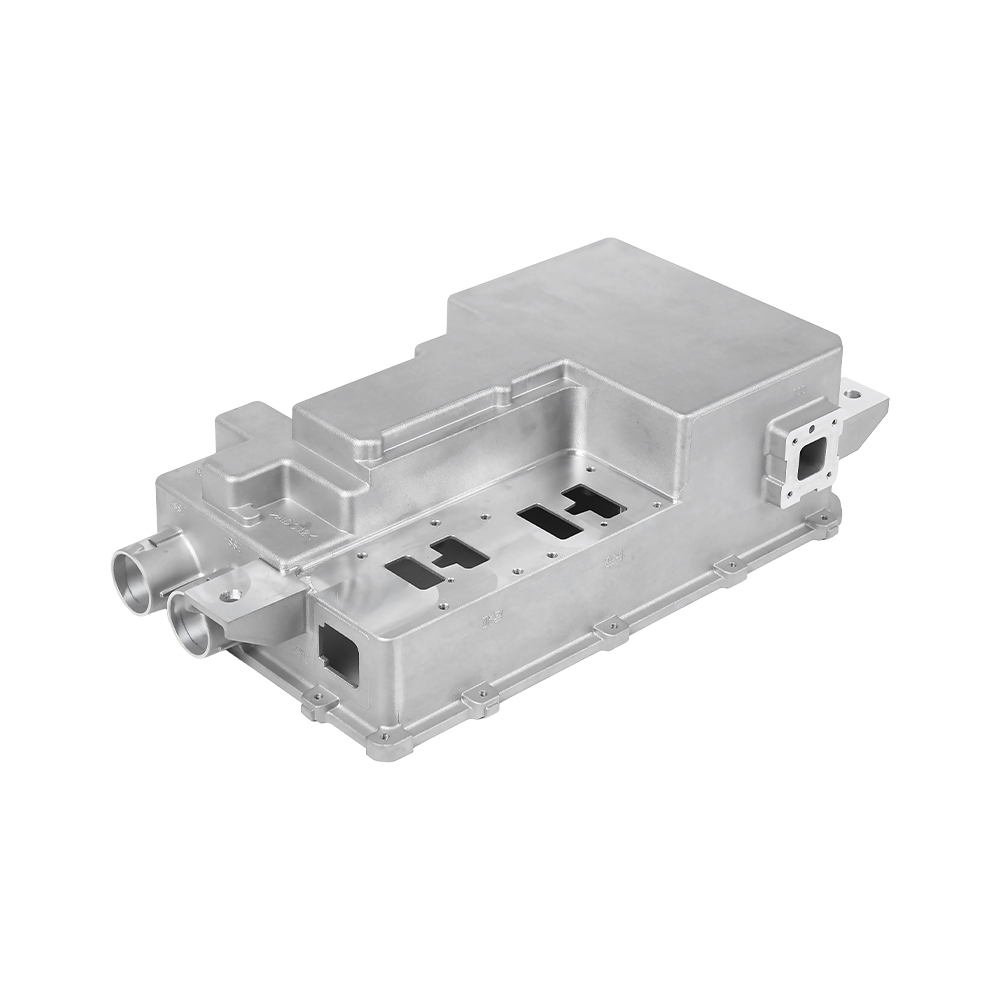

New Energy Vehicle Heat Dissipation Aluminum Substrate

Cat:Aluminum Die Casting

This new energy vehicle utilizes an aluminum alloy substrate for heat dissipation, employing high-qu...

See Details -

Aluminum Die Cast Motor Housing 375

Cat:Aluminum Die Casting

Aluminum Die Cast Motor Housing 375 is a kind of metal shell used to protect the motor. Its main fun...

See Details -

Opening Machine Accessories

Cat:Aluminum Die Casting

Aluminum pressure casting is the main part of the aluminum pressure die-casting machine, manufacture...

See Details -

Aluminum Die Casting Hydraulic Valve

Cat:Aluminum Die Casting

Aluminum die-casting hydraulic valve represents a pinnacle of engineering precision and efficiency i...

See Details -

Aluminum Die Casting Gasoline Engine Case

Cat:Aluminum Die Casting

Aluminum die casting for gasoline engine cases is a sophisticated manufacturing process that plays a...

See Details -

Car Air Conditioning Aluminum Compressor Cylinder

Cat:Aluminum Die Casting

Our aluminum engine cylinder block is a high-quality automotive component made from high-purity alum...

See Details -

Aluminum Die Casting Gearbox Body

Cat:Aluminum Die Casting

High Precision: Utilizing precision aluminum alloy die-casting technology ensures the product's dime...

See Details -

Aluminum Bearing Bracket

Cat:Aluminum Die Casting

The Aluminum Bearing Bracket is a crucial mechanical component employed to support and secure bearin...

See Details -

Auto Engine Cooling Water Pump

Cat:Aluminum Die Casting

This product is an efficient automotive engine cooling water pump, manufactured using high-quality m...

See Details -

Aluminum Casting Accessories Aluminum End Cap

Cat:Aluminum Die Casting

This Aluminum Casting Accessory, the Aluminum End Cap, is crafted from high-quality aluminum alloy m...

See Details -

New Energy Vehicle Heat Dissipation Aluminum Substrate

Cat:Aluminum Die Casting

This new energy vehicle utilizes an aluminum alloy substrate for heat dissipation, employing high-qu...

See Details -

Aluminum Die Cast Motor Housing 375

Cat:Aluminum Die Casting

Aluminum Die Cast Motor Housing 375 is a kind of metal shell used to protect the motor. Its main fun...

See Details -

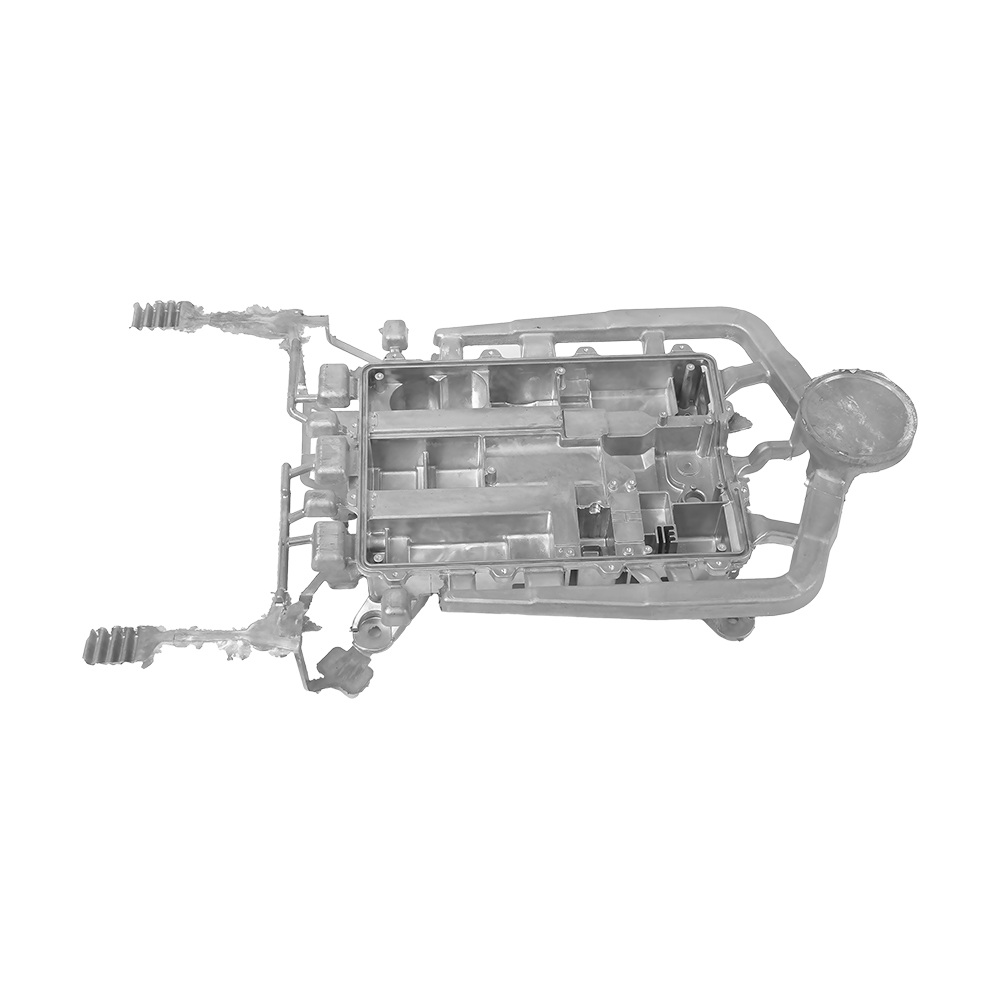

Opening Machine Accessories

Cat:Aluminum Die Casting

Aluminum pressure casting is the main part of the aluminum pressure die-casting machine, manufacture...

See Details

As a professional a China custom Aluminum Cast Car Engine Parts Oil Pump manufacturers and Aluminum Cast Car Engine Parts Oil Pump suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

-

Aluminum die-casting technology can be used to produce oil sump for engine oil chambers, and has multiple advantages, especially suitable for complex, high load bearing, and high-strength components. ...

READ MORE -

Aluminum die-casting can be used to produce complex engine cylinder blocks and heads, especially in the trend of lightweight development in automobiles, where the application of aluminum alloy die-cas...

READ MORE -

The parts produced by aluminum die-casting process do require post-treatment in most cases, in order to improve their surface quality, mechanical properties, functional adaptability, and meet the fina...

READ MORE

Aluminum cast car engine parts oil pump Do I need to monitor the engine temperature and water pump working status in real time?

Aluminum cast car engine parts oil pumps usually require real-time monitoring of engine temperature and water pump working status to ensure the normal operation of the engine cooling system and extend the service life of the engine. The following is a detailed analysis of this requirement:

1、 The importance of real-time monitoring of engine temperature

Prevent overheating: The engine generates a large amount of heat during operation. If the cooling system cannot effectively dissipate heat, the engine temperature will rise sharply, which may lead to excessive thermal stress, component damage, and even engine failure. Real time monitoring of engine temperature can detect and take measures to reduce the temperature in a timely manner, preventing the occurrence of overheating.

Optimize engine performance: The engine exhibits different performance characteristics at different temperatures. Keeping the engine running within an appropriate temperature range can ensure optimal performance in terms of power, fuel efficiency, and emissions. Real time monitoring of engine temperature helps adjust the working status of the cooling system to maintain the optimal operating temperature of the engine.

2、 The importance of real-time monitoring of the working status of water pumps

Ensure coolant circulation: The water pump is a critical component of the engine cooling system, responsible for driving the coolant to circulate inside the engine. If the water pump malfunctions, such as impeller damage, bearing wear, or seal failure, it will cause poor coolant circulation or leakage, seriously affecting the engine's heat dissipation effect. Real time monitoring of the working status of the water pump can detect potential problems in a timely manner and avoid cooling system failure.

Preventing malfunctions: By monitoring the operating parameters of the water pump in real-time (such as speed, vibration, temperature, etc.), its working status and remaining life can be predicted. Taking timely measures for maintenance or replacement when abnormal situations are discovered can effectively prevent water pump failures, reduce downtime and maintenance costs caused by failures.

3、 Implement real-time monitoring methods

Install sensors: Install temperature sensors and vibration sensors near the engine and water pump to monitor the engine temperature and water pump operation status in real time. Sensors transmit the collected data to the vehicle's control system or fault diagnosis system for processing and analysis.

Using fault diagnosis systems: Modern cars are usually equipped with advanced fault diagnosis systems (such as OBD-II systems), which can monitor the working status of components such as the engine and water pump in real time and store relevant fault information. When a fault is detected, the system will light up the fault indicator light on the dashboard and allow technicians to use diagnostic tools to read fault codes and related information for diagnosis and repair.

In summary, the oil pump of aluminum cast car engine parts requires real-time monitoring of engine temperature and water pump working status to ensure the normal operation of the engine cooling system and extend the service life of the engine. This real-time monitoring can be achieved through the installation of sensors and the use of fault diagnosis systems.

Address Dalun Mould Venture Park, Beilun, Ningbo, Zhejiang, China

Tel +86 13586867000

E-mail cindy@youyuandiecasting.com

2021 © All Rights Reserved by Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd. Aluminum Cast Car Engine Parts Oil Pump manufacturers custom Aluminum Cast Car Engine Parts Oil Pump suppliers

English

English русский

русский Español

Español